Alloy Wheel Casting Process

Kneading casting mold structure. Here the alloy metal is melted and pour in special pressure stamps.

The Wheel Development Part Iii Aez News

After analyzing the structure and properties of.

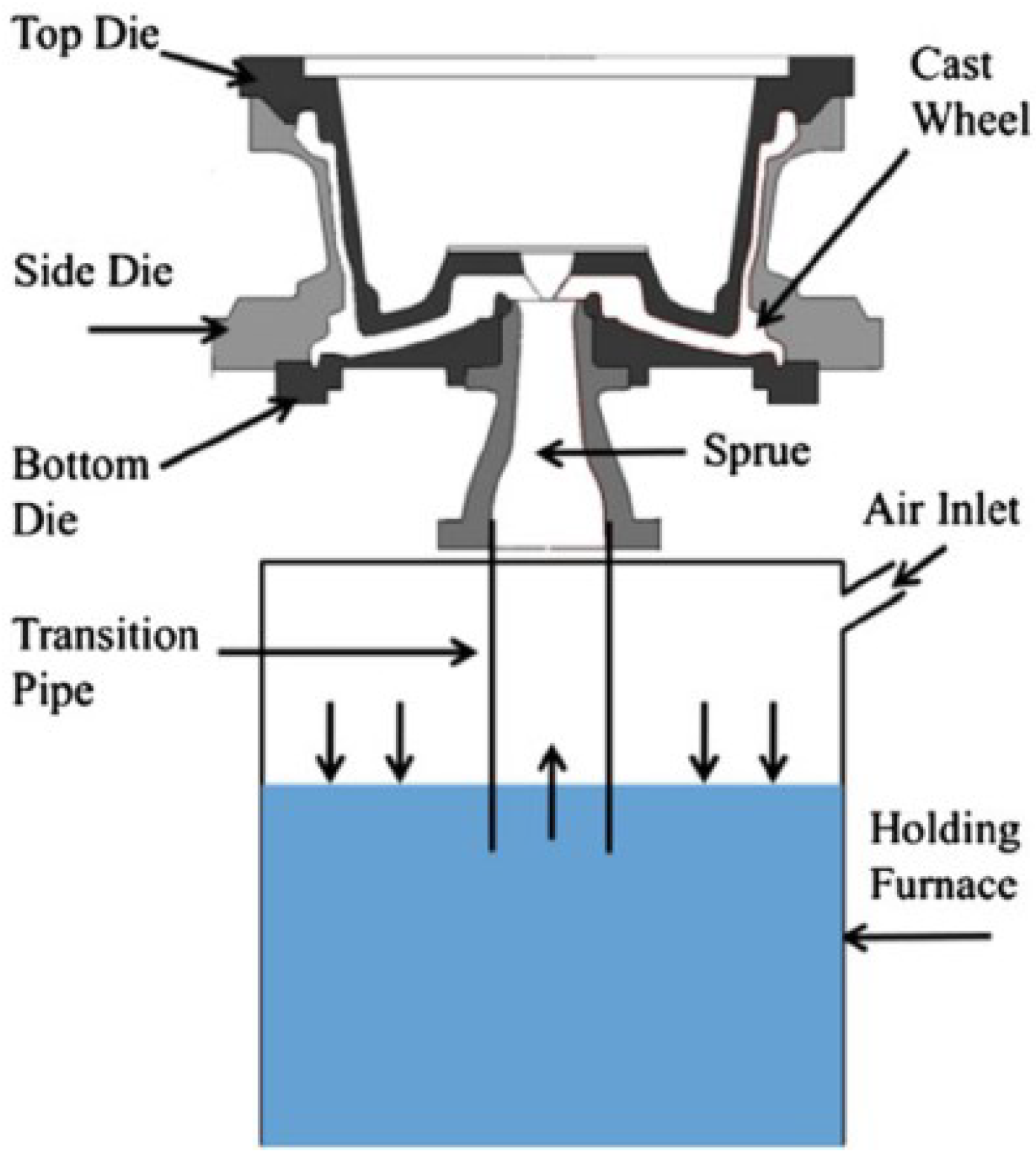

. Optimization Of Casting Process For Low-Pressure Casting Aluminum Alloy Wheels 21 Low-pressure casting aluminum alloy technology. The manufacturing process also includes die- casting technology. Aluminum alloy casting wheel hub is refined into crucible and coke furnace.

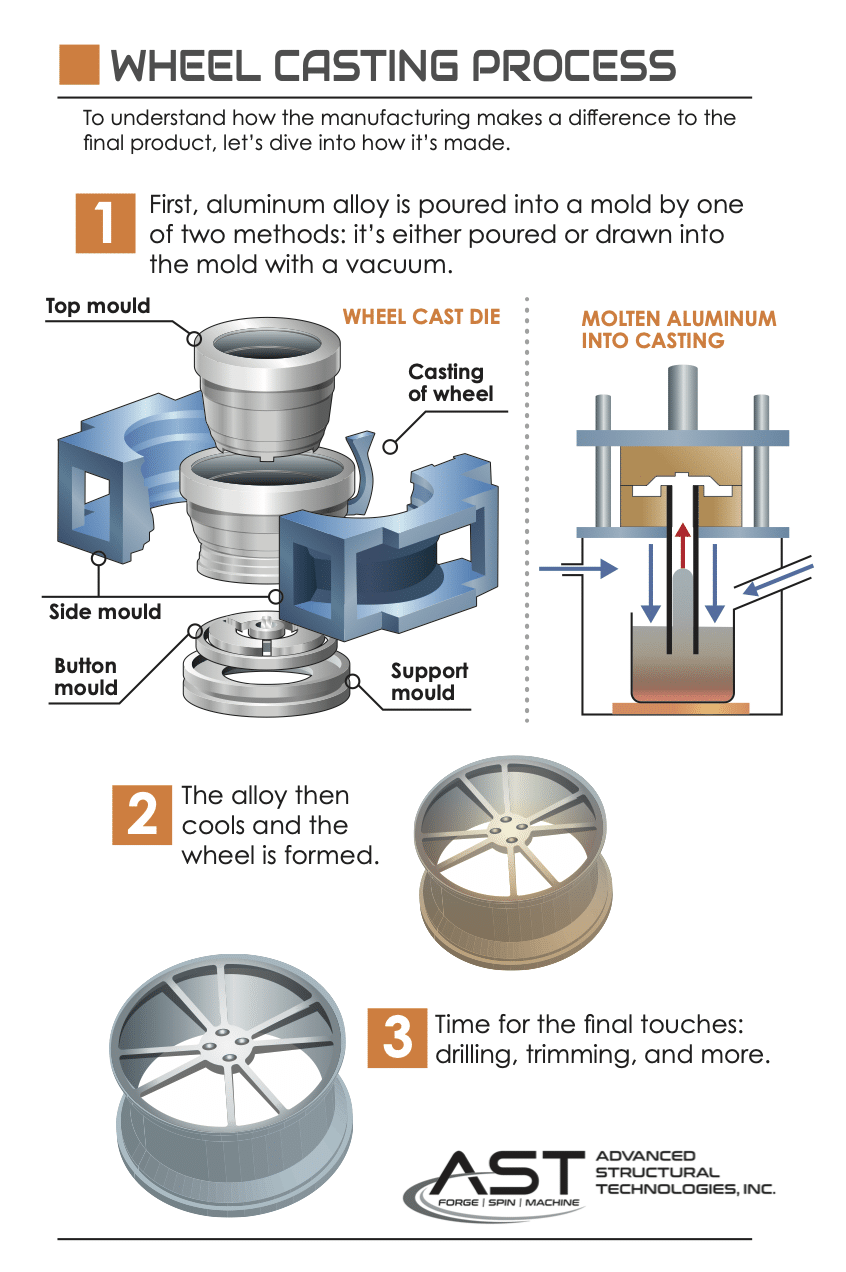

It mainly has the required cavity composed of convex mold right. A gravity cast aluminum wheel uses the most basic process of pouring molten aluminum into a mold utilizing the earths gravity to fill the mold. The mold structure for kneading and casting of aluminum alloy wheels is shown in Figure 3.

Our trip starts in the GMP Italia fusion laboratory. Cost of alloy wheels. Up to 5 cash back Gravity Casting.

Finally alloy wheels undergo a heat treatment process to make them durable and resistant to corrosion. View Record in. There are three main problems in this regard.

The feed rate for thinning and spinning of aluminum alloy wheels is selected in the range of 053mmr. 1 aluminum alloy materials is carried out melting and obtains aluminum liquid the percentage by weight of aluminum liquid Main Ingredients and Appearance is Si 6872 Mg 455 Ti 01015 Fe 00501 and the. The result is an absolutely perfect.

The commonly used feed rate is 0515mmro. JOM 65 2013 pp. Aluminium alloy wheels casting process The method of making Aluminum Alloy castings using permanent mold.

Process modeling of low-pressure die casting of aluminum alloy automotive wheels. The forming angle of the wheel is. However some casting defects often appear in the casting process which seriously affect the quality of aluminum alloy casting hub so an in-depth analysis will be carried out.

The manufacturing process also includes the costs of alloy wheels the rigidity and cost of die-casting technology and the Heat treatment procedure. In simple terms gravity casting is mainly based on the gravity of aluminum water to fill the mold which is an early casting method. The invention discloses the low-pressure casting process of a kind of aluminium alloy wheel hub low-pressure casting process comprises the following steps.

Metals Free Full Text Advanced Process Simulation Of Low Pressure Die Cast A356 Aluminum Automotive Wheels Part I Process Characterization Html

Flow Forming Technology An Advance In The Wheel Manufacturing Industry

Pdf Computer Simulation Of Casting Process Of Aluminium Wheels A Case Study Semantic Scholar

Cast Vs Flow Formed Vs Forged Wheels The Real Difference

0 Response to "Alloy Wheel Casting Process"

Post a Comment